OEM Factory Gasoline Injector Tester And Cleaner Ultrasonic Injector Cleaner

- group name

- Injector Cleaner & Tester

- Min Order

- 1 set

- brand name

- Zeayeto

- model

- FIC-601

- Nearest port for product export

- Shenzhen, HongKong

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CIP, DDP, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

- update time

- Tue, 25 Jun 2019 16:57:17 GMT

Paramtents

color red

Application Car injector

Usage Injector cleaning & testing

Certification CE

Warranty 1 Year

Power 230W

Input voltage AC 220V

Gross weight 27 KG

Size 400mm*400mm*580mm

Packging & Delivery

- 60cm x60cm x42cm

-

Min Order1 set

Briefing

Detailed

OEM Factory Gasoline Injector Tester And Cleaner Ultrasonic Injector Cleaner

Description

When the quality of gasoline is poor or the vehicle is running for a long time, if the injector is not cleaned for a long time, the clogging phenomenon will be more serious, causing poor engine fuel injection, poor fuel injection angle and atomization, resulting in engine idling and acceleration. In the case of full-load working conditions, the engine power is reduced, the fuel consumption is increased, the pollution is increased, and the engine is not working. Therefore, the injector should be carefully cleaned regularly to ensure it works well.

Parameters

Model Number | FIC-601 |

Voltage | AC 220V±10% |

Frequency | 50/60Hz |

Relative humidity | <85% |

Net Weight | 27kg |

Ambient temperature range | -10°C~40°C |

Size | 40*41*58cm |

Function

1. Sealing test function: It can detect the sealing and dripping of the injector under system pressure.

2. Fuel injection detection: It can detect the fuel injection amount of the fuel injector within the set time.

3. Automatic cleaning detection function: Under the specific working condition parameters, the real simulation of the injector is tested under various working conditions.

4. Fuel system free cleaning and cleaning function: With a variety of non-removable cleaning joints, it can be used for cleaning and maintenance of various models.

Compared with traditional methods

The traditional nozzle cleaning device uses a "slinging bottle" method to clean the injector. This method does not visually see the cleaning effect, and it has only a cleaning function and no detection function. Time-consuming and labor-intensive. A new generation of injector inspection and cleaning machines, integrated detection and cleaning, can more intuitively observe the cleaning effect.

Working principle

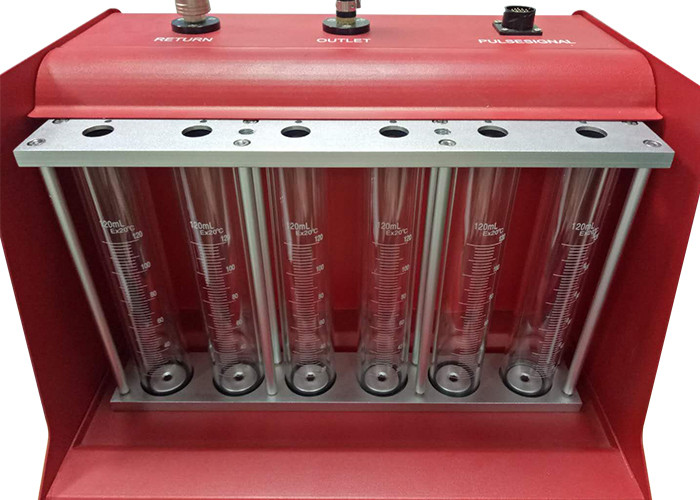

Through the set pressure value, the oil in the oil pump is supplied to the fuel injection nozzle through the oil-distributing pump, and then the fuel injector sprays the oil into the vector cup, and the performance of the fuel injector can be detected by watching the measuring cup. Simulate the working condition of the injector when the car is working. Image and visualization.

Reverse flush

Injector Cleaner& Tester can also perform reverse flush by connecting with flush-back adaptor at [Uniformity/Sprayability test] mode. Reverse flush is a way to clean the injectors with the test liquid flowing from the outlet to the inlet of the injector. Reverse flush may remove the dirt inside the injector or the injector Strainer(0nly for the top fuel supply injector).

Note:

1. The system pressure can be adjusted by pressing [reduce pressure]/[boost pressure] key when performing reverse flush.

2. It is advisable to press[Drain] key to avoid spillover of test liquid during reverse flush.